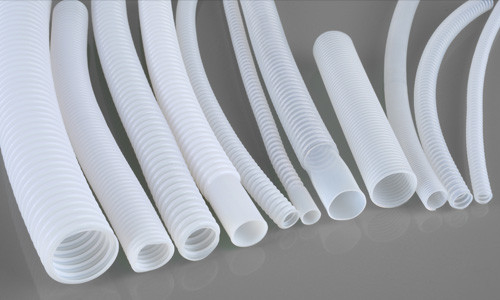

Convoluted PTFE Tube for Electronic liquid Cooling System

Convoluted PTFE tube offers a compelling solution for electronic liquid cooling systems. Its combination of chemical resistance, temperature stability, flexibility, and high purity makes it an ideal choice for demanding applications where reliability and performance are critical.

Key Advantages:

1. Chemical Inertness: PTFE is virtually inert to most chemicals, including coolants, acids, and bases. This ensures long-term performance and prevents contamination of the cooling fluid.

2. Temperature Resistance: PTFE can withstand extreme temperatures, from cryogenic to high temperatures, making it suitable for a wide range of electronic cooling applications.

3. Flexibility: The convoluted design provides excellent flexibility, allowing for easy installation and routing in confined spaces.

4. Abrasion Resistance: The smooth inner surface minimizes friction and reduces the risk of particle abrasion, ensuring long-term system reliability.

5. High Purity: PTFE is a non-toxic and non-reactive material, making it suitable for applications where fluid purity is critical.

Electrical Insulation: PTFE is an excellent electrical insulator, minimizing the risk of electrical shorts within the cooling system.

Applications in Electronic Liquid Cooling:

Server Racks: Cooling high-density server racks requires efficient heat dissipation. PTFE hoses can effectively transport coolant to and from heat exchangers, ensuring optimal cooling performance.

Data Centers: In large-scale data centers, convoluted PTFE hoses can be used to build complex cooling loops, enabling efficient heat removal from a large number of servers.

High-Performance Computing: High-performance computing systems generate significant heat. PTFE hoses can effectively manage heat dissipation, ensuring stable and reliable operation of these critical systems.

Edge Computing: In edge computing applications, where space is often limited, the flexibility of PTFE hoses allows for efficient routing and installation of cooling systems.

Specification:

| Spec. |

Cuff O.D. |

Cuff I.D. |

CON O.D. |

W.P |

B.P |

MIN. B.R |

|

| |

mm |

inch |

mm |

inch |

mm |

inch |

psi |

bar |

psi |

bar |

mm |

inch |

| 6x8 |

8 |

0.315 |

6 |

0.236 |

9.4 |

0.37 |

60 |

4 |

210 |

14 |

20 |

0.787 |

| 8x10 |

10 |

0.394 |

8 |

0.315 |

10.8 |

0.425 |

60 |

4 |

210 |

14 |

22 |

0.866 |

| 10x12 |

12 |

0.472 |

10 |

0.394 |

11.8 |

0.465 |

60 |

4 |

210 |

14 |

26 |

1.024 |

| 13x15 |

15 |

0.591 |

13 |

0.512 |

17.9 |

0.705 |

60 |

4 |

210 |

14 |

26 |

1.024 |

| 16x18 |

18 |

0.709 |

16 |

0.63 |

21.9 |

0.862 |

45 |

3 |

180 |

12 |

32 |

1.26 |

| 19x21 |

21 |

0.827 |

19 |

0.748 |

26.4 |

1.039 |

45 |

3 |

180 |

12 |

55 |

2.165 |

| 19x22 |

22 |

0.866 |

19 |

0.748 |

26.4 |

1.039 |

45 |

3 |

150 |

10 |

65 |

2.559 |

| 25x28 |

28 |

1.102 |

25 |

0.984 |

35 |

1.378 |

30 |

2 |

135 |

9 |

100 |

3.937 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!