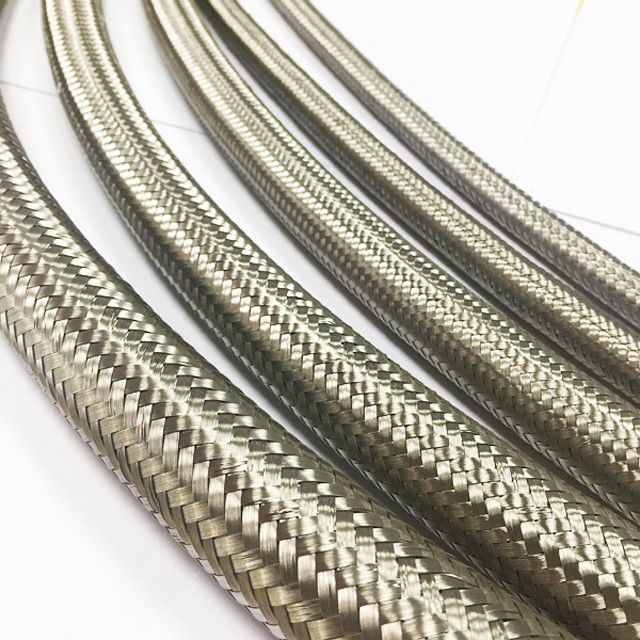

Flame Resistant AISI 304 Over Braided PTFE Hose For Automobiles

PTFE Tube Key properties

Excellent chemical resistance

Working temperature from -180°C to +260°C

FDA approved

Flame resistant - UL94V0

No stick

Low friction

Very good dielectric insulation properties

Construction: Tube: Domestic PTFE / The imported F-205 of Japan Daikin

Cover: SS304 / SS316 Braided

Temperature: -50℃ to +200℃ (Domestic Material)

-50℃ to +260℃ (Imported Material)

Application: Mainly used for conveying various chemicals, ships, automobiles, Marine industry machinery hydraulic system etc

Coil length: 50~150m (Random Length).

Standard: SAE100 R14

Connector: Customize as per request

| Inner Diameter |

Outer Diameter |

Working Pressure |

Burst Pressure |

Min. Bending Radius |

Thickness |

Approx. Weight |

| inch |

mm |

mm |

bar |

Bar |

mm |

mm |

Kg/m |

| 1/8" |

3.2 |

6.6 |

320 |

988 |

51 |

1 |

0.07 |

| 3/16" |

4.8 |

7.7 |

242 |

726 |

75 |

0.85 |

0.09 |

| 1/4" |

6.4 |

9.3 |

210 |

653 |

81 |

0.85 |

0.11 |

| 5/16" |

7.9 |

10.8 |

188 |

587 |

92 |

0.85 |

0.15 |

| 3/8" |

9.5 |

12.7 |

185 |

556 |

131 |

0.85 |

0.17 |

| 1/2" |

12.7 |

16.3 |

106 |

461 |

182 |

1 |

0.31 |

| 5/8" |

15.9 |

19.3 |

127 |

382 |

211 |

1 |

0.47 |

| 3/4" |

19 |

22.3 |

78 |

269 |

338 |

1.2 |

0.57 |

| 7/8" |

22.2 |

26.2 |

60 |

195 |

421 |

1.2 |

0.7 |

| 1" |

25.4 |

29.8 |

40 |

153 |

539 |

1.5 |

0.8 |

| 2’’ |

50 |

55.6 |

30 |

120 |

1015 |

2 |

1.5 |

Normal Packing: opp film and woven strips wrapped

Customized Packing: Non-fumigation pallet or Wooden reels

|

Hose I.D

|

Length roll |

|

3/16'' ~ 1/2''

|

100~150m |

|

5/8'' ~ 1''

|

50~100m |

Competitive Advantage

1, Passion PTFE hose is made of virginal PTFE, with Excellent high temperature & corrosion resistance.

2, Hot sale in America, Canada, Germany, Mexico. Bulk hose

3, Free Sample is available / Hose assembly is available

About Paishun

Paishun factory covers a land of over 3 hectares, and the workshops occupy a surface of 25000 square meters. We own complete production lines of the rubber mixing process, cold feeding material extrusion process, microwave vulcanization process, and high-speed braiding process, etc.

We produce mainly industrial hoses like Air Hose, Water Hose, Oil Hose, Welding Hose, Hydraulic Hose, and Assemblies. Paishun, being a rapidly growing enterprise focusing on the professional production of pure rubber hoses and braided rubber hoses, its yearly production capacity reaches 10 million meters.

Our key policy is "enterprise may thrive with the technology, and may last with good quality". So we put much investment in the research team, and in advanced testing laboratory equipment. We now use a series of tensile testing machines, vulcanization testing devices, aging testing chest, pressure testing machines to ensure effective quality control. All these testing machines and related procedures may form a complete quality control system, beginning from the selection of the raw materials till the end step. Thus, we wish our products can satisfy in maximum of our customers, and help them to gain more and more market share.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!